- FDM 3D Printers

Consumer 3D Printers

Professional 3D Printer

Composite 3D Printer

Consumer 3D Printers

Professional 3D Printer

Composite 3D Printer

- Resin 3D Printers

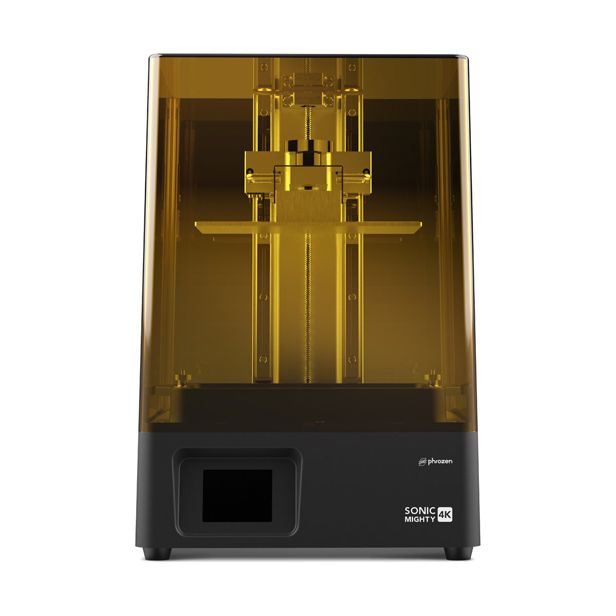

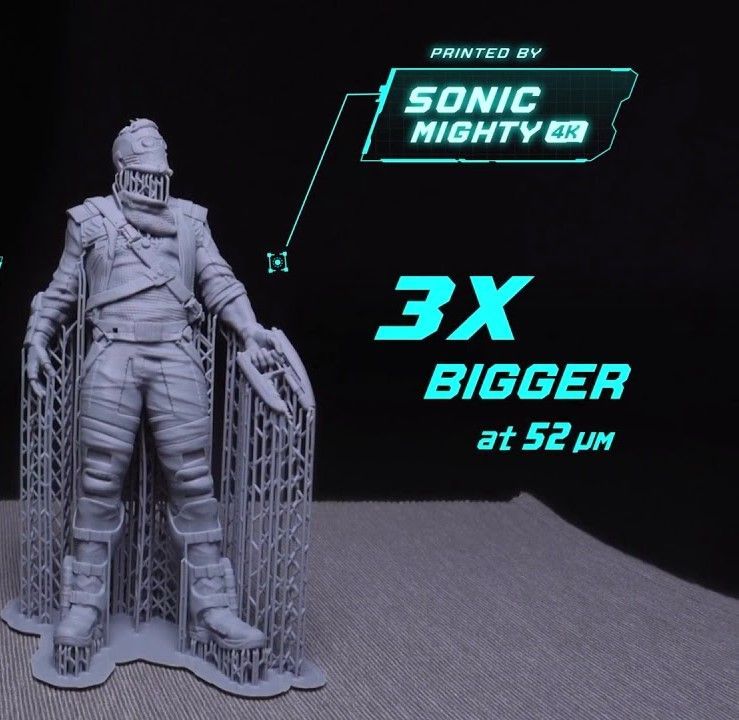

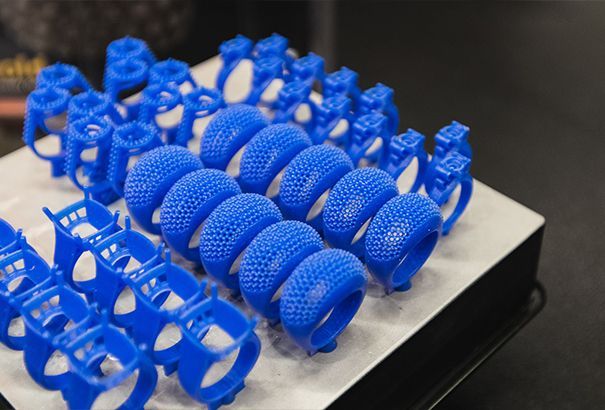

LCD 3D Printers

SLA 3D Printers

DLP 3D Printers

SLA 3D Printers

DLP 3D Printers

- Industrial 3D Printers

- Materials

- Services

PRODUCT DESIGN & DEVELOPMENT

PROTOTYPING

ARTICLES

PRODUCT DESIGN & DEVELOPMENT

PROTOTYPING

ARTICLES

- Medical

ARTIFICIAL PROSTHETIC HANDS

PRE – SURGICAL PLANNING

ARTICLES

ARTIFICIAL PROSTHETIC HANDS

- Learn

- FDM 3D Printers

Consumer 3D Printers

Professional 3D Printer

Composite 3D Printer

Consumer 3D Printers

Professional 3D Printer

Composite 3D Printer

- Resin 3D Printers

LCD 3D Printers

SLA 3D Printers

DLP 3D Printers

SLA 3D Printers

DLP 3D Printers

- Industrial 3D Printers

- Materials

- Services

PRODUCT DESIGN & DEVELOPMENT

PROTOTYPING

ARTICLES

PRODUCT DESIGN & DEVELOPMENT

PROTOTYPING

ARTICLES

- Medical

ARTIFICIAL PROSTHETIC HANDS

PRE – SURGICAL PLANNING

ARTICLES

ARTIFICIAL PROSTHETIC HANDS

- Learn

- FDM 3D Printers

Consumer 3D Printers

Professional 3D Printer

Composite 3D Printer

Consumer 3D Printers

Professional 3D Printer

Composite 3D Printer

- Resin 3D Printers

LCD 3D Printers

SLA 3D Printers

DLP 3D Printers

SLA 3D Printers

DLP 3D Printers

- Industrial 3D Printers

- Materials

- Services

PRODUCT DESIGN & DEVELOPMENT

PROTOTYPING

ARTICLES

PRODUCT DESIGN & DEVELOPMENT

PROTOTYPING

ARTICLES

- Medical

ARTIFICIAL PROSTHETIC HANDS

PRE – SURGICAL PLANNING

ARTICLES

ARTIFICIAL PROSTHETIC HANDS

- Learn