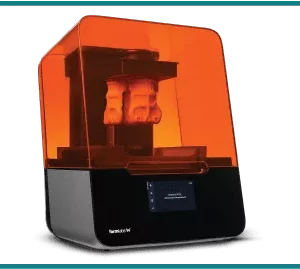

A Versatile 3D printer suitable for both Office and Production facilities.

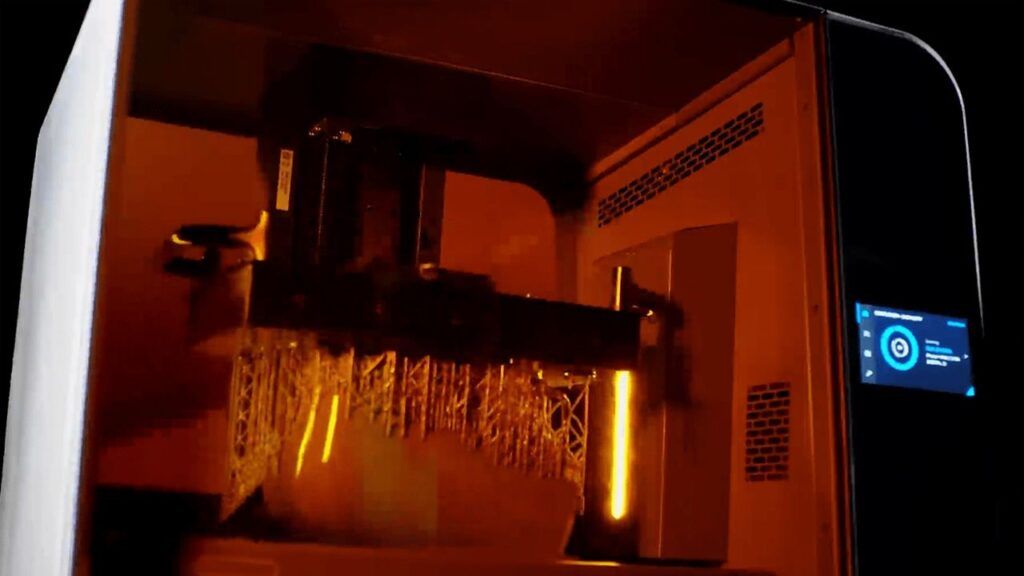

Equip your batch production with reliable Formlabs Form 3L, a large format SLA 3D printer available in Pakistan that can bring your ideas to reality at a premium quality.

Form 3L requires minimal supervision with the print jobs. Built-in sensors and control system maintain ideal print conditions for batch production and large-sized parts

Printing Technology

Low Force Stereolithography (LFS)™

Resin Filling System

Automated

Build Volume (W x D x H)

33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in)

Minimum Access Dimensions (W × D × H)

90 × 96 × 104 cm (35.4 × 37.8 × 41 in)

Printer Dimensions (W × D × H)

77 × 52 × 74 cm (30.3 × 20.5 × 29.1 in)

Layer Thickness (Axis Resolution)ᵇ

25 – 300 microns (.001 – .012 in)

XY Resolution

25 microns (0.001 in)

Laser Spot Size

85 microns (0.0033 in)

Resin Cartridges

2

Biocompatible Materials

No

Internal Temperature

Auto-heats to 35 °C (Auto-heats to 95 °F)

Temperature Control

Air-heated print chamber

Operating Environment

18 – 28 °C (64 – 82 °F)

Weight

54.4 kg (120 lb)

Power Requirements

100–240 VAC, 2.5 A, 50/60 Hz, 220 W

Laser Specifications

2 Light Processing Units, EN 60825-1:2007 certified, Class 1 Laser Product, 405 nm wavelength, 250 mW power, 85 micron (0.0033 in) laser spot

Connectivity

Wi-Fi (2.4, 5 GHz), Ethernet (1000 Mbit), USB 2.0

Printer Control

5.5″ interactive touchscreen, 1280 × 720 resolution

Alerts

Touchscreen alerts, SMS/email via Dashboard, Two LED status indicators, Speaker for audio alerts

System Requirements

Windows 7 (64-bit) and up, Mac OS X 10.12 and up, OpenGL 2.1

4 GB RAM (8 GB recommended)

PreForm Print Setup Features

One-Click Print, Adaptive layer thickness for faster printing with fine details, Remote Print, Auto-orient for optimal print position, Auto-mesh repair, Auto-generation of supports, Rotate, scale, duplicate, and mirror, Layer slicer for path inspection, Available in multiple languages

Dashboard Printer Management Features

Manage prints and printers via the cloud, Track resin and tank usage over time, SMS and email alerts

Create enterprise group accounts with admins to more easily share printers and control acces

File Types

STL and OBJ file input, FORM file output

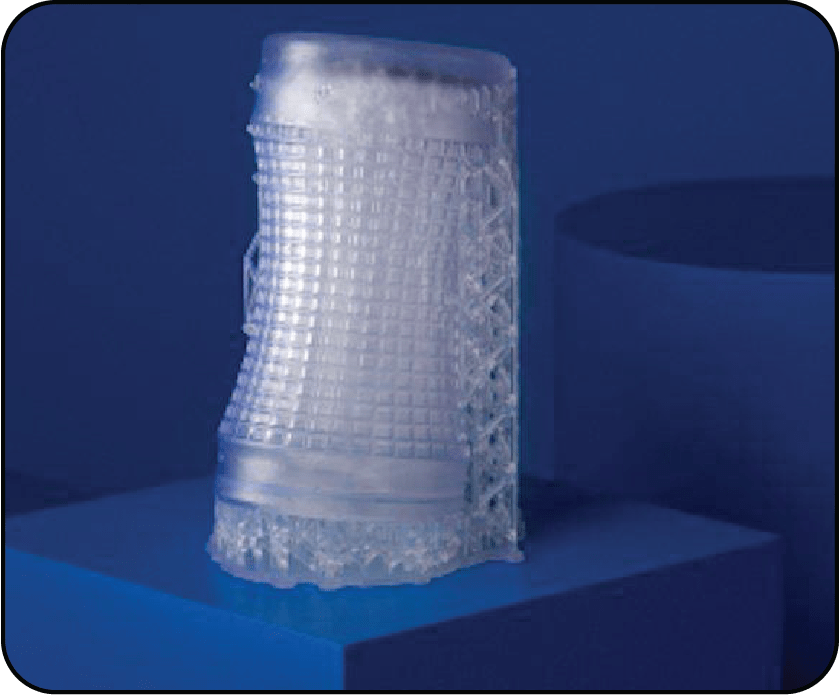

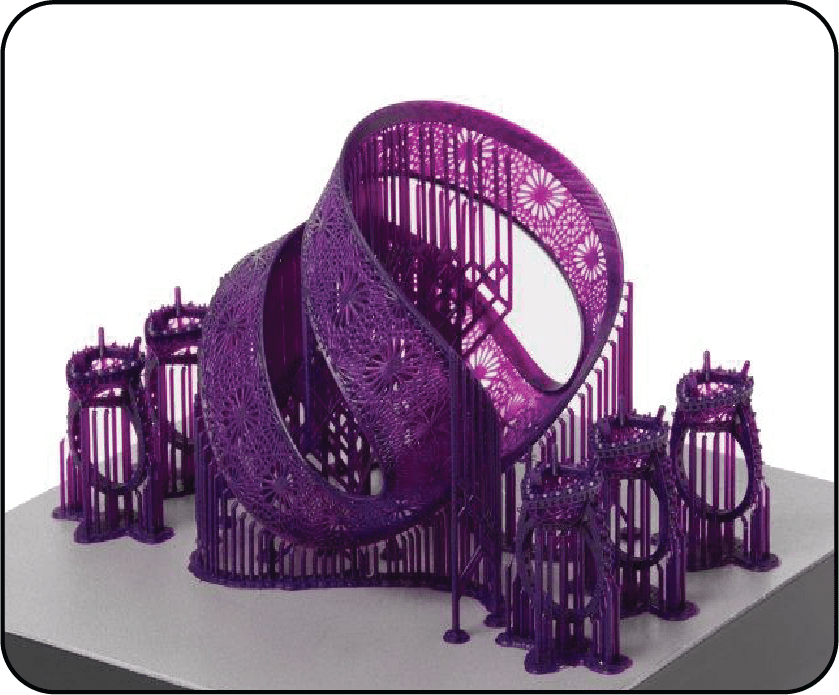

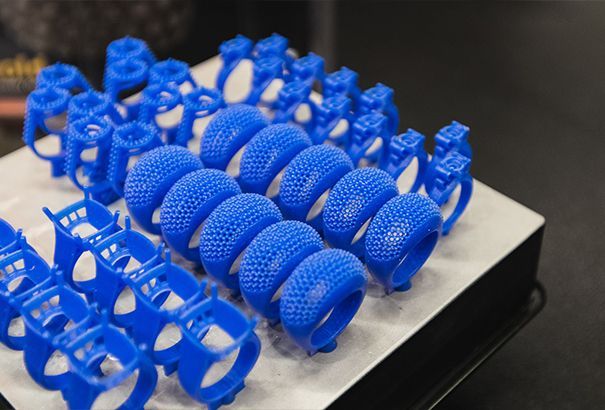

Along with the exceptional functional reliability, Formlabs Form 3L offers versatile compatibility with numerous materials.

Excellent Fluidity, no residue, no ash, ultra clean burnout

Excellent casting of small engravings, Fast Curing, No need of post-curing, Best for Direct Casting

COMPANY

SERVICES