PRODUCT

CATEGORIES

PRODUCT

TAGS

MATERIALS

Filaments

Resin

Search by Text

Search by Brand

- Universal(0)

- Ultimaker(36)

- Sunlu(40)

- Resione(0)

- Raise 3D(1)

- Qidi Tech(1)

- ProtoSpeed(0)

- PolyMaker(11)

- Phrozen(0)

- Novafab(0)

- Meanwell(0)

- MatterHacker(1)

- JamgHe(18)

- Insize(0)

- Grit 3D(0)

- Everest(11)

- Esun(9)

- Eryone(5)

- Ender(4)

- Elegoo(0)

- Creality(27)

- BlueCast(0)

- BASF(2)

- Bambulab(2)

- Anycubic(0)

- Antinsky(0)

- 3dx Tech(1)

Filter by Price

₨ -

Product categories

- 3D Printer Filaments

- ABS Filaments

- ABS Creality

- ABS Esun

- ABS Sunlu

- ABS Ultimaker

- ABS-CF Everest

- PA-CF polymaker

- Esilk Filaments

- Esilk Creality

- Esilk Eryone

- Esilk Sunlu

- PC Filaments

- PC Bambulab

- PC BASF

- PC Filaments Qidi Tech

- PC Filaments Raise 3D

- PC Matterhacker

- PC Ultimaker

- PC-CF Filaments 3dx Tech

- PC-MAX Filaments

- PC-MAX Polymaker

- PET-G Filaments

- PET-G Creality

- PET-G Sunlu

- PET-G Ultimaker

- PETG Filaments

- PETG-CF Everest

- PLA Filaments

- Hi Speed PLA JamgHe

- PLA Creality

- PLA Ender

- PLA Eryone

- PLA Esun

- PLA Everest

- PLA Jamghe

- PLA Polymaker

- PLA Sunlu

- Ultimaker PLA

- PP Filaments

- PP BASF

- PP Ultimaker

- Tough PLA Filaments

- Tough PLA Ultimaker

- TPU Filaments

- TPU Creality

- TPU Sunlu

- TPU Ultimaker

Stock status

- In Stock

- Out of Stock

- On Backorder

-

Esun White ABS 1.75 mm

₨ 4,800.0 Read more -

Creality White ABS+ 1.75 mm

₨ 5,500.0 Read more -

Sale!

Creality Red PLA Filament 1.75mm

₨ 5,800.0Original price was: ₨ 5,800.0.₨ 5,600.0Current price is: ₨ 5,600.0. Add to cart Buy Now -

Sale!

Creality Yellow PLA Filament 1.75mm

₨ 5,800.0Original price was: ₨ 5,800.0.₨ 5,500.0Current price is: ₨ 5,500.0. Add to cart Buy Now -

Sale!

Creality Grey PLA Filament 1.75mm

₨ 5,800.0Original price was: ₨ 5,800.0.₨ 5,500.0Current price is: ₨ 5,500.0. Add to cart Buy Now -

Sale!

Creality Blue PLA 1.75mm

₨ 5,800.0Original price was: ₨ 5,800.0.₨ 5,500.0Current price is: ₨ 5,500.0. Add to cart Buy Now -

Sunlu Matte Black PLA 1.75 mm

₨ 5,500.0 Read more -

Sale!

Creality Matte Black PLA 1.75mm

₨ 5,800.0Original price was: ₨ 5,800.0.₨ 5,500.0Current price is: ₨ 5,500.0. Read more -

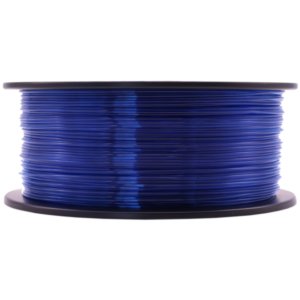

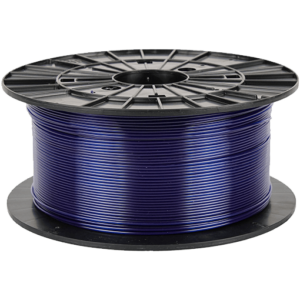

Creality Transparent Blue PET-G 1.75 mm

₨ 5,000.0 Read more -

Creality Transparent PET-G 1.75 mm

₨ 5,500.0 Read more -

Sale!

Sunlu Transparent PET-G 1.75 mm

₨ 4,800.0Original price was: ₨ 4,800.0.₨ 4,500.0Current price is: ₨ 4,500.0. Read more -

Sale!

Sunlu Transparent Blue PET-G 1.75 mm

₨ 4,800.0Original price was: ₨ 4,800.0.₨ 4,500.0Current price is: ₨ 4,500.0. Read more -

Creality White PET-G 1.75 mm

₨ 4,200.0 Read more -

Creality Black ABS 3D Filament 1.75mm

₨ 5,500.0 Read more -

Creality Red ABS 1.75mm

₨ 5,500.0 Read more -

Creality Grey ABS 1.75mm

₨ 5,500.0 Read more -

Sale!

Creality Blue ABS 1.75mm

₨ 5,000.0Original price was: ₨ 5,000.0.₨ 4,600.0Current price is: ₨ 4,600.0. Read more -

Sale!

Creality White ABS Filament 1.75mm

₨ 5,500.0Original price was: ₨ 5,500.0.₨ 4,800.0Current price is: ₨ 4,800.0. Add to cart Buy Now -

Creality White TPU 1.75mm

₨ 5,500.0 Read more -

Creality Black TPU 1.75mm

₨ 4,500.0 Read more -

Creality Grey TPU 1.75mm

₨ 4,500.0 Read more -

Creality White Silk 1.75 mm

₨ 5,000.0 Read more -

Creality Red Silk 1.75 mm

₨ 5,000.0 Read more -

Creality Yellow Silk 1.75 mm

₨ 5,000.0 Read more

No products were found matching your selection.

PRODUCT CATEGORIES

PRODUCT TAGS

MATERIALS

- Filaments

- Resin

MATERIALS

- Filaments

- Resin

COMPANY

SERVICES